MIT nanotube technique suggests greener way to make aeroplane parts

MIT engineers have found a new way to create aerospace-grade carbon-fibre composites using only one per cent of the energy of current methods, and none of the ovens and autoclaves.

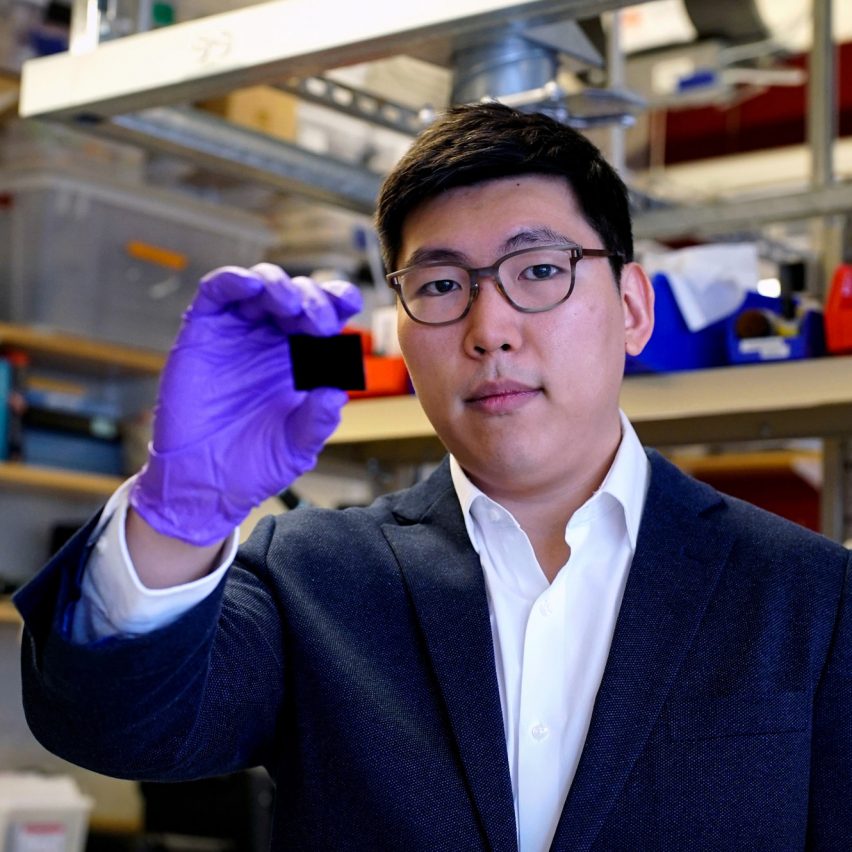

The development comes from Massachusetts Institute of Technology engineers working with carbon nanotubes ? hollow tubes of carbon atoms that are thinner than human hair but stronger than steel.

They found that sheets of these carbon nanotubes can be used "like an electric blanket" to fuse the composite materials for aeroplanes, spacecraft and other large structures such as wind turbines.

No ovens or pressure chambers

They describe these structures as being made of layers of different composite materials like a filo pastry.

Currently, fusing these materials securely means cooking them in giant ovens and sucking any air bubbles out in autoclaves ? industrial pressure chambers. This process only happens once the materials are moulded into the shape of a fuselage or other required part, necessitating warehouse-size facilities.

The MIT researchers' technique does away with the need for these ovens and autoclaves, and potentially speeds the whole process up.

Reducing air pockets took time

They initially succeeded with the out-of-oven (OoO) technique ? which requires wrapping the materials in ultra-thin carbon nanotube sheets and then applying an electric current to heat them up ? in 2015.

This produced composites as strong as the materials made with traditional methods, using just one per cen...

| -------------------------------- |

| Héctor Zamora erects curved brick wall Lattice Detour on The Met rooftop |

|

|

Villa M by Pierattelli Architetture Modernizes 1950s Florence Estate

31-10-2024 07:22 - (

Architecture )

Kent Avenue Penthouse Merges Industrial and Minimalist Styles

31-10-2024 07:22 - (

Architecture )