MIT Self-Assembly Lab's Rapid Liquid Printing technology produces furniture in minutes

A team of researchers at the Massachusetts Institute of Technology has developed a 3D printing method that is considerably faster and can work at a much larger scale than current processes.

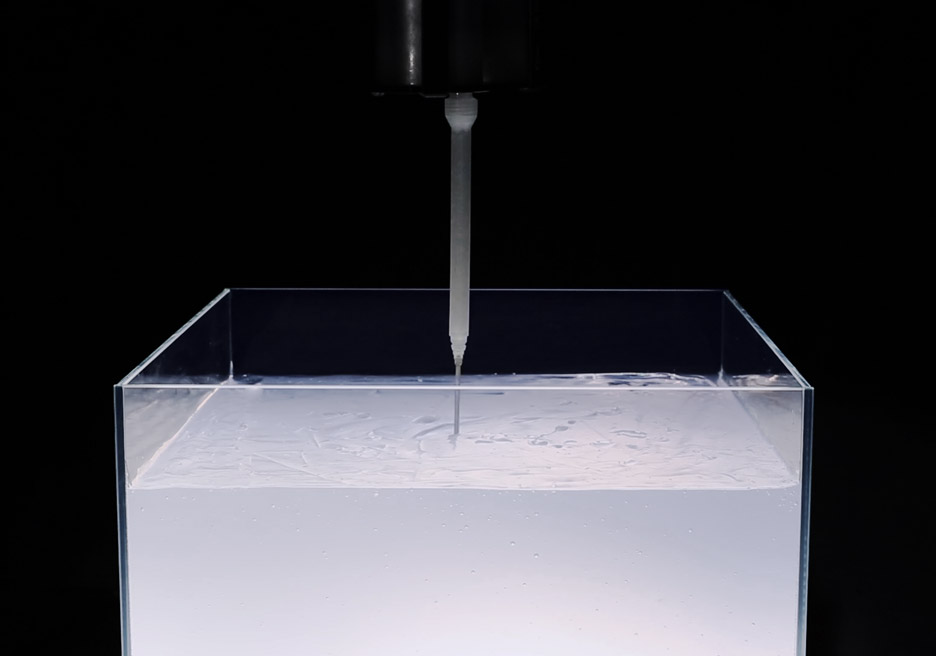

The Self-Assembly Lab worked with US furniture company Steelcase to develop the process known as Rapid Liquid Printing, which involves extruding material from a computer-controlled nozzle into gel.

This allows them to print large-scale structures very quickly, creating a range of possibilities for furniture production.

"In the beginning we started with this question: could you print furniture in minutes"" lab director Skylar Tibbits told Dezeen. "If you look at printing from that perspective it forces you to think about it in a completely different way."

The team's aim was to tackle the three main challenges that they believe have prevented 3D printing's widespread adoption in manufacturing: speed, scale and material properties.

"Most of the time we can only print centimetre-scale structures, and for furniture, it's unfeasible," said Tibbits.

"There are a couple of reasons why the properties aren't so good," he added. "Nearly every printing process utilises layers, and those layers degrade the structural property of the material compared to a consistent material all the way through."

Rapid Liquid Printing allows the robotic aperture to draw freely in 3D space, constrained only by the size of the tank.

The gel, similar to hair gel...

| -------------------------------- |

| Could unused parking structures be used as apartments" | Architecture | Dezeen |

|

|

Villa M by Pierattelli Architetture Modernizes 1950s Florence Estate

31-10-2024 07:22 - (

Architecture )

Kent Avenue Penthouse Merges Industrial and Minimalist Styles

31-10-2024 07:22 - (

Architecture )